- #QUICKMENU OSCILLOSCOPE IMG UPDATE#

- #QUICKMENU OSCILLOSCOPE IMG DRIVER#

- #QUICKMENU OSCILLOSCOPE IMG CODE#

#QUICKMENU OSCILLOSCOPE IMG CODE#

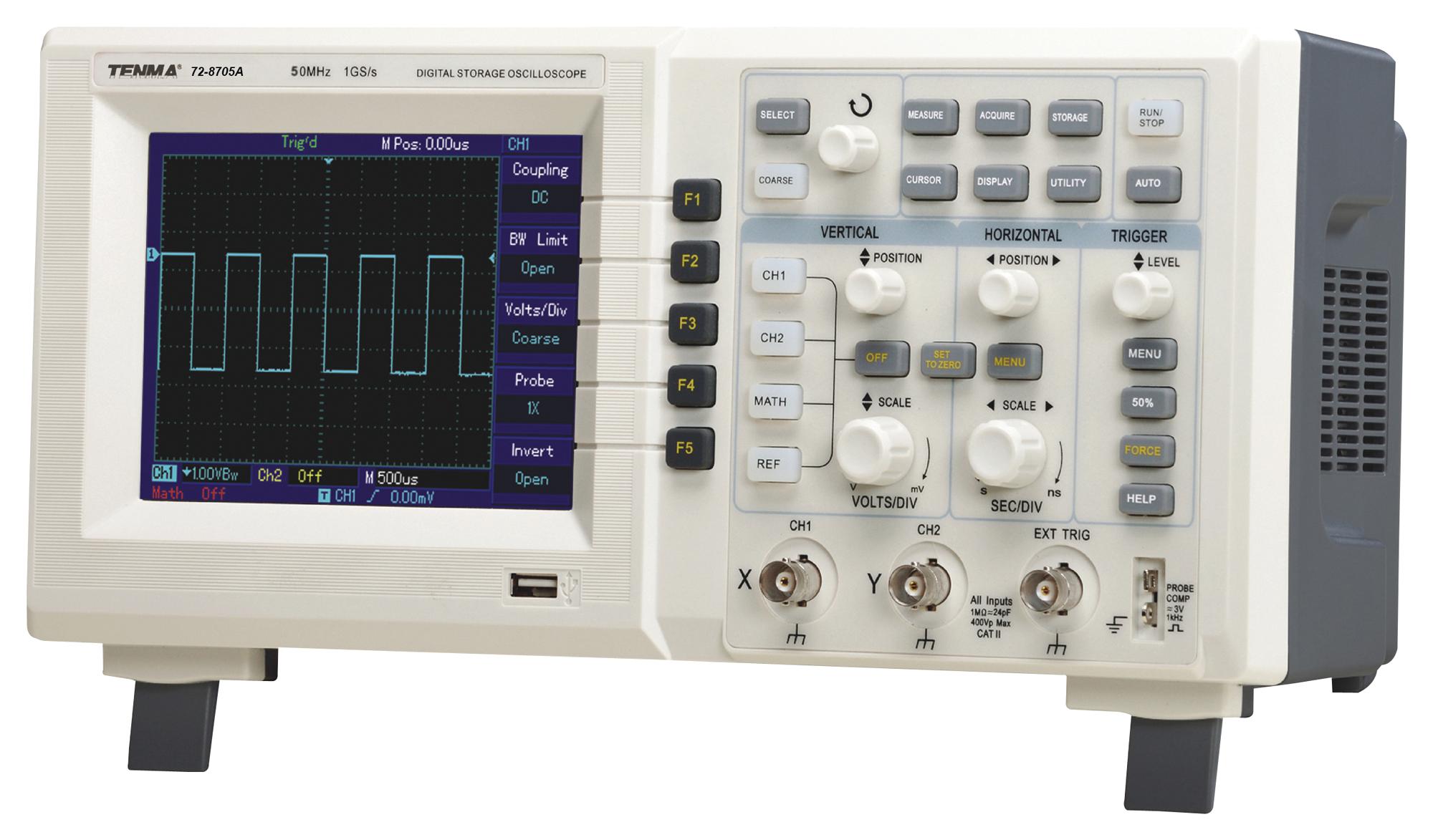

After getting the Butterfly to generate a voltage for every non-white pixel, was impressed with the results so the code was modified determine the brightness of each pixel. A friend wrote a Python script to generate C code so the ports of the Butterfly can be toggled. He was able to to draw a line on the oscilloscope’s screen but bandwidth limitations forced him to reconsider his approach. started out with a resistor ladder on the DAC of his AVR Butterfly. When the new mosfet‘s arrive I will bolt it back together and I can then check for signals etc but would like to be prepared to know what to look for and so on.Was curious one day and decided that he wanted to display graphics on an oscilloscope after playing around with the X and Y inputs. Does anyone know what the LED’s signify and how many there should be in total ? Updated: I have found this - HCPL0611 Fairchild Optocoupler Ģ) the person who has a look at it, was satisfied that the input stage of the machine is ok and that the LED’s on the board show green. I would be interested to know:-ġ) which component in the photos above is the opto isolator, ( I am not near the machine now to look closely at it) I have ordered 6 new mosfet‘s just so that I know I have good ones. Removing the board there is no obvious signs of burnt out components. I had some one look at it and he spoke to Lincoln who want £3,250 for a new circuit board and mosfets. I still get the HF start spark but no more. I did not use it regularly, but went to use it a few weeks back and it initially worked and then stopped. Hope that someone in need and use this post and I want to special thanks to Bobbesfor helping me. So tig welding was very hard work and ist not similar to soldering

Still working on it and now I am learning to make master of TİG welding. I have seen all signals and supply voltages are ok and the machine working good with all functions except trying welding.įinally, replace mosfets with IXFN80N50 and test it for all functions 3 days throughout. I Applied to +15 and -15 volt by lab type power supply to proper connections on board and drive by signal genarator of after UC3854 output circuit between gates of mosfets and fixing easly broken IC HCPL0611 by this way.Īfter replace HCPL0611 with temporarly cheaper mosfets for trying to control all circuits as normal conditions as seen on photo. Externaly drive and test it by oscilloscope. Stay only one way to test this kind of circuits.

Because most probably faulty gate circuit is apply positive signal pulsed or DC continuously to mosfets gates and mosfets burn instantly on first second cause mosfets always trying to stay on state.

#QUICKMENU OSCILLOSCOPE IMG DRIVER#

This kind of fault, you can not test gate driver circuits as working normal operation of like on my machine. My first check PFC driver mosfets was broken. On this machine (Invertec V205T AC DC), PFC site mosfets are driving between -5V to +15V PWM signal producing by UC3854 which is fixed frequency PWM IC. I used to IXFN80N50 which is equavelent of APT50M50JVFR. Normally must be installed APT50M50JVFR but someone have used GB75DA120UP IGBT on my machine.

#QUICKMENU OSCILLOSCOPE IMG UPDATE#

First of all, need to a small update for type of MosFets.

0 kommentar(er)

0 kommentar(er)